In today’s modern production environment visualization is not only important, it is essential.

Visualization is one of the cornerstones of ThinManager and building your ultimate control room to see everything in your production environment is simply put… “A Piece of Cake”!

Start by obtaining a capable thin client, one that can support multiple monitors. We like a configuration for at least 4 large monitors. Need suggestions, look at the ThinManager Knowledge Base of ThinManager ready hardware. Install and layout your monitors.

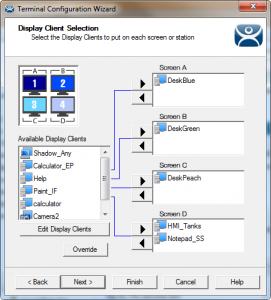

Using ThinManager you can now assign your control room thin client with all the applications, HMIs, IP Camera Feeds and Desktops that you will need to operate in complete control with optimal visualization of what is happening in your production environment.

Using ThinManager you can now assign your control room thin client with all the applications, HMIs, IP Camera Feeds and Desktops that you will need to operate in complete control with optimal visualization of what is happening in your production environment.