The proliferation of the Internet has created the largest interconnected network of machines the world has ever known. Our connected world is so complex that no one person or group understands everything that is needed to maintain the network and keep it in a healthy state.

The effort to maintain the network as “up” is constant. No matter where you live, someone near you is working right now to prevent something or stop something from losing its connected state. They may work just as tirelessly to get something back online that has lost its connection to everything else.

Of course, most of us never concern ourselves with these issues until we lose our connection to everything else. This scenario recently happened when many woke up to the CrowdStrike outage that caused major business disruptions over the last few weeks, especially for airlines and healthcare agencies.

This is a Big Deal

This issue is a big deal because it demonstrates the real dangers, and highlights the fragility, of a connected world of computers. Almost all these computers have an operating system. If you are unfamiliar, the operating system, or OS, is the intelligence behind every computer.

Even though operating systems are all around us now (PCs, phones, cars, etc.) most of them get updated automatically. The average person does not, and will not, take the time to manage this task manually. Many businesses cannot manage this job any better than individuals. This fact is why businesses like CrowdStrike exist. These datacenters oversee computer systems used by third parties. These third parties rely on their providers to take care of managing and distributing these updates in a planned, secure manner. Good news – this system works most of the time!

The problem is, when it fails, the failure can be wide and catastrophic. The recent CrowdStrike issue is being called the largest outage in IT history.

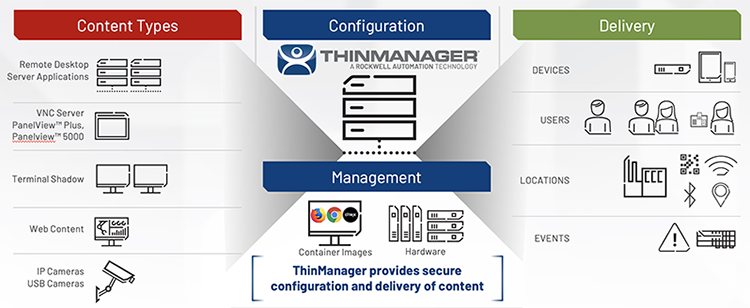

So if we know that any device connected to a network is exposed to the possibility of being compromised, what steps can organizations take to mitigate the risks associated with a fully connected enterprise? Since making everything less connected is not an option for most businesses, other solutions must be sought. [...]