More and more industrial manufacturers are realizing the benefits of using thin client computing technology to run their modern facilities. We recently had the chance to speak with Thanh Phan from Quantum Solutions about how they used ThinManager to build out a new food production facility in the Midwest.

When one of the world’s largest food and beverage companies wanted to open a new processing plant in Davenport, Iowa, they called on their partners at Rockwell Automation to help them design and implement a modern, connected workspace.

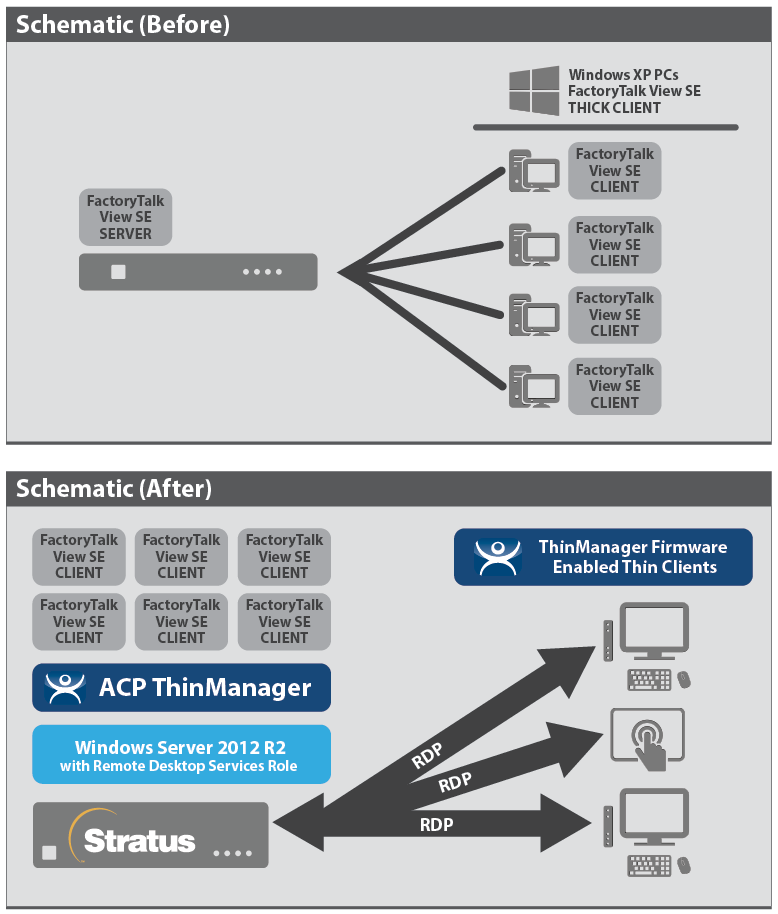

Since the network services group from Rockwell Automation was already managing the networks for the customer, Dan Neiner, Senior Engineer for Rockwell Automation, was involved with the project from the onset. The customer wanted to implement a thin client strategy for this new facility. The old plants had used PCs, and the customer wanted to move away from the time and expense necessary to keep PCs up and running in their production environments.

Because the solution required thin clients, Dan called on his systems integrator partners at Quantum Solutions. Quantum not only had thin client experience, but they had ThinManager experience. They were chosen by the customer to lead this deployment.

Thanh Phan with Quantum Solutions knew ThinManager was the right solution for their customer. It’s the only thin client system designed specifically for industrial application delivery and management.

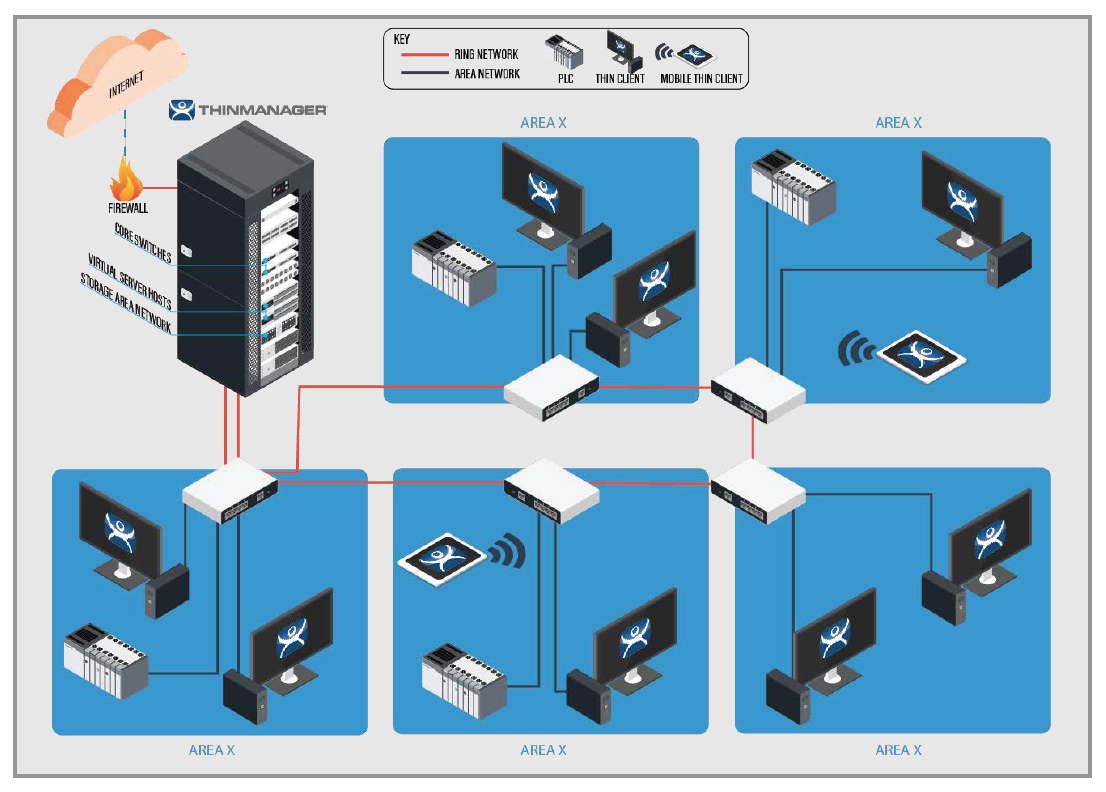

The customer’s new plant is very large, coming in at almost 385,000 square feet with a staff of around 475 people. It was designed to replace an existing plant that had operated for decades. Quantum’s plan for deploying ThinManager and FactoryTalk View SE consisted of 3 Remote Desktop Servers and 2 ThinManager Servers that would manage and deliver content to 48 industrial thin clients.

The servers and applications that run this ThinManager solution are driven and supported from a Rockwell Automation Integrated Data Center (IDC). This packaged solution not only runs the applications that ThinManager delivers, but it also runs the network and is securely managed by Rockwell Automation technical support professionals.

Simplicity Equals Productivity

There is more than one reason the team from Quantum chose ThinManager to deploy FTView SE to the thin clients in this plant. “All the requested functionality that our customer needed for this deployment was already integrated into ThinManager in a simple way,” stated Phan. “Other convenient features such as TermMon ActiveX, virtual keyboard and simple touchscreen calibration solidified ThinManager as the final choice.”

Phan continued, “The TermMon ActiveX provided reboot and screen calibration functionality directly from the HMI. We were able to apply a script to the reboot process that ensured the thin client logged out of the server and restarted, etc. in a specific order. This also eliminated the need for physical keyboards for calibration. When a keyboard is needed, ThinManager’s hold-time configuration allows operators easy access to a virtual keyboard. We were able to configure the virtual keyboards to persist for only 5 seconds ensuring the keyboard never got in the way of other hold events on screen.”

Safety and Security are Built-In

Safety and Security were also important aspects of this food and beverage deployment. In addition to the built-in security of thin client hardware, Quantum deployed two of ThinManager’s most powerful features—AppLink and Shadowing.

“AppLink guaranteed that operator access at the thin client would be limited only to the HMI application. This ensured that the server could not be accessed from the thin client. This was an absolute requirement, by the customer, for this deployment,” said Phan.

“Shadowing allows us to troubleshoot issues remotely. Not only can we see what the operator sees, but we can take control of a terminal while an operator is standing by. Working in tandem with TermMon, we can remotely reboot a terminal after making updates to the HMI,” Phan explained.“We also took advantage of ThinManager on the server side. First, all of the users in ThinManager are synced with Active Directory so system access can still be managed by IT. Also, by using SmartSession, we are able to load balance all three HMI servers. This makes the entire thin client delivery method much more robust and improves availability in the event of server failover.”

This is a textbook example of how ThinManager benefits systems integrators by providing solutions designed for specifically the industrial manufacturing customers they serve. We asked Thanh Phan if Quantum planned to deploy ThinManager for future customer thin client deployments.

“Absolutely!” Phan replied. “While the program itself is straightforward, easy to learn, and takes little time to set up—the time saved and travel expenses avoided as a result of allowing engineers to remote in to a plant’s system and solve problems without having to appear on site is really what puts ThinManager above the other platforms we have used.’

“As an example,” Phan continued,”after our initial on-site setup, the customer experienced small problems that we were able to solve in 15-30 minutes, over the phone, using the Shadow and TermMon ActiveX features. If these features were not readily available, it could have meant a trip out to the customer, resulting in additional travel costs that would otherwise be unnecessary. At the very least, it would have resulted in an additional loss of time.’

“While instances like those listed above do not occur on a frequent basis,” Phan admitted,”when the customer does happen to have a problem, ThinManager’s features keep it from becoming an expensive one.”

Project Overview

Required deployment for new plant startup with following customer requests:

- 48 thin clients

- Failover for applications

- Restrictions on operator access to servers

- Simple thin client replacement in event of hardware failure

Fit for ThinManager:

- All requested functionality already integrated into ThinManager

- Other convenient features (such as TermMon ActiveX, virtual keyboard, simple screen calibration) solidified ThinManager as the final choice

Quantum readily agreed to ThinManager being used as the platform of choice for several reasons:

Quantum’s first choice for these systems with other customers is already always ThinManager.

ThinManager is very simple to set up and straightforward to use even for those that are not familiar with the platform.

The Shadow feature enabled the ability to effectively troubleshoot problems remotely.

[...]