When one of Canada’s oldest operating dairy facilities needed to update their aging facility, they partnered with PID Engineering to create a modern visualization solution.

“Our customer needed to upgrade their outdated server running obsolete HMI software. This was putting their factory at greater risk of unreliability and downtime without support,” stated Jonah Renouf from PID. “We installed a Stratus Server and wanted to utilize ThinManager® to manage the client-based delivery system for HMI production screens throughout the plant.”

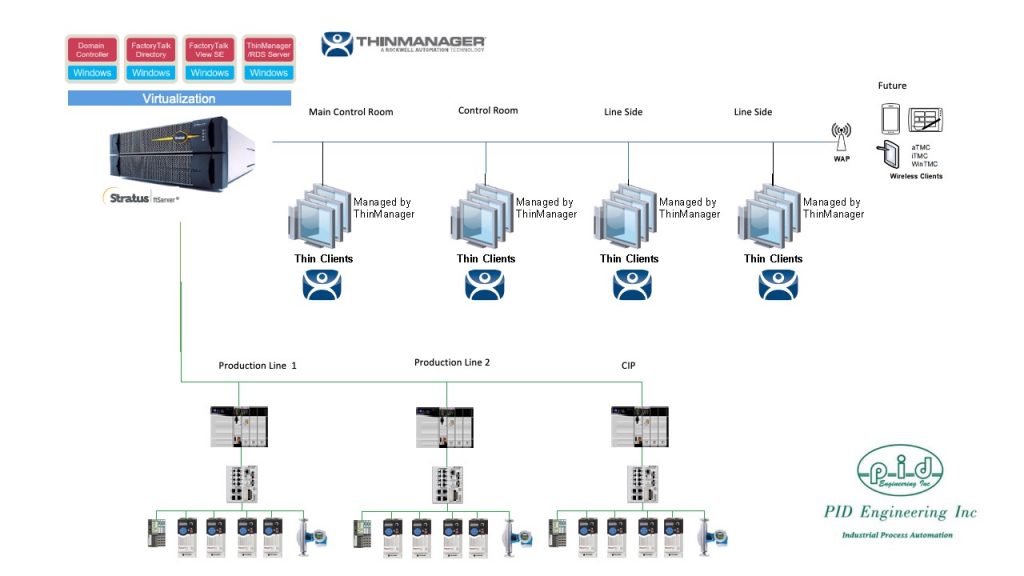

Renouf continued, “The Stratus Server uses VMWare’s ESXi-Vsphere as the operating manager for the Stratus Server. The ESXi-Vsphere includes four Virtual Machines that each serve a different purpose. One machine is for editing the software such as FactoryTalk and XLReporter, one is for Engineering and changing the PLC Programming on RSLogix 5000, one is for the Thin Manager Server which hosts the ThinManager Applications and the Client Files, and finally one is for the Data Collection or Historian which acts as a backup Virtual Machine for Data Collection Purposes and holds the Active Directory of Users.”

“As the rebuilding of the software infrastructure was being implemented at the dairy plant, the server was built around the idea of simplifying outdated software and updating any older versions of the screens. Updating the screens from the previous HMI to FactoryTalk View and utilizing Rockwell solutions was the intended outcome of this solution. ThinManager created a relatively simple way to implement the ideas necessary to execute the project,” said Renouf.

Renouf went on to explain how ThinManager’s MultiSession capability allows for optimal client usage within each proper station. “The versatility of allowing different sessions to monitor the dairy production process creates redundant security for production. They realized additional savings by using MultiMonitor at specific stations in the plant. This feature allows for the operator to use dual screens to interact with two different areas in the HMI client at once, cutting down interruptions and easing workflow.”

“Terminal Shadowing, available to administrators, was equally important as specified process screens can be monitored from multiple views. Terminal shadows can also be viewed from any other terminal connected to the ThinManager server, when needed,” he stated.

“Our customer also plans to add mobile clients. This will allow operators on the floor to monitor the system when away from traditional, tethered workstations. ThinManager can deliver the same content to mobile devices that is delivered to thin clients.”

“As a Rockwell SI partner, we have installed ThinManager in other facilities and have had good success. Our company is familiar with the visualization solutions from Rockwell Automation and we typically request that ThinManager be the application of choice for managing thin clients due to its flexibility and easy integration,” Renouf concluded.

PID Engineering Inc. develops, designs, and automates liquid flow and process control systems for major international manufacturers from the raw liquid ingredient through to the finished pasteurized product specializing in Dairy processing. Our innovative programming methods provide professional quick process integration from the factory floor processing systems and the operators. Since its foundation in 1993 PID Engineering has been developing custom industry solutions for its customers in the food & beverages industry as well as the pharmaceutical and other liquid and semi liquid processing industries.