Using ThinManager to Drive a Cutting Edge Facility

For years, businesses and governments have been talking more and more about the environmental impact of modern industrial manufacturing processes and the costs associated with conventional energy sources such as coal and oil. That combined with the projected increase in fossil fuel consumption in countries such as China and India has lead to a resurgence of new investment and research in the renewable energy commercialization sector.

For years, businesses and governments have been talking more and more about the environmental impact of modern industrial manufacturing processes and the costs associated with conventional energy sources such as coal and oil. That combined with the projected increase in fossil fuel consumption in countries such as China and India has lead to a resurgence of new investment and research in the renewable energy commercialization sector.

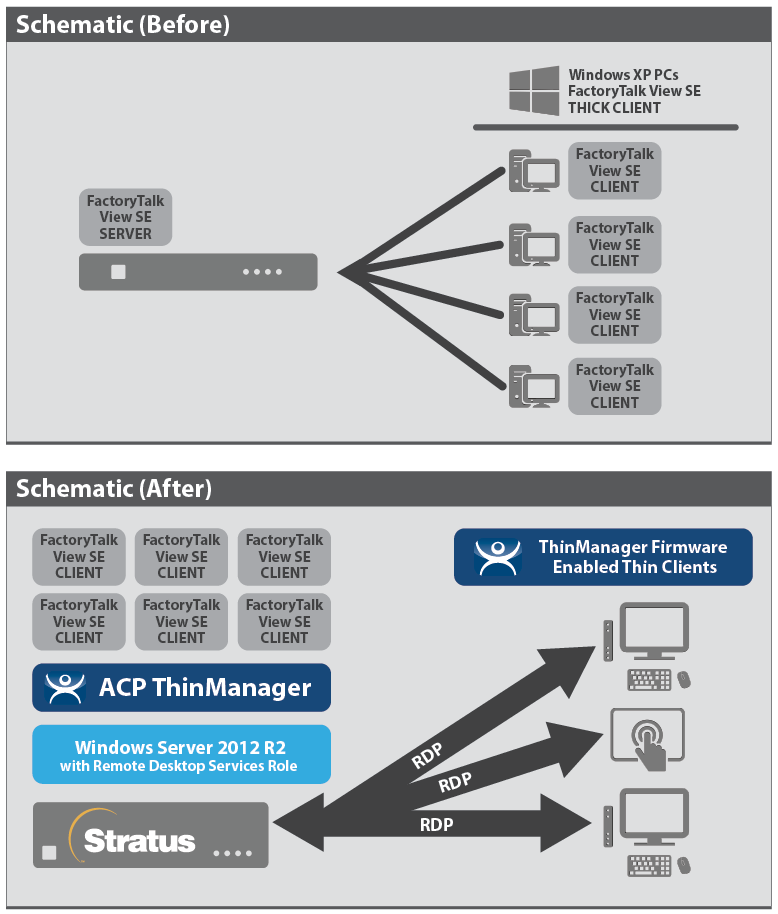

Robert Maxfield, the Vice President and Control System Architect of Third Evolution, recently got to see just how cutting edge companies can be in this sector while deploying ThinManager in a new state of the art facility specializing in Biomethane capture and processing. “Our client originally came to us wanting to implement a Citrix XenDesktop thin client architecture into one of their existing facilities. Having worked with it before, I knew that ThinManager was much easier to deploy and operate as well as offering greater management capabilities, so I offered to show them proof of concept of our proposed architecture using Wonderware InTouch and ThinManager instead. After seeing it in person, they were sold.”

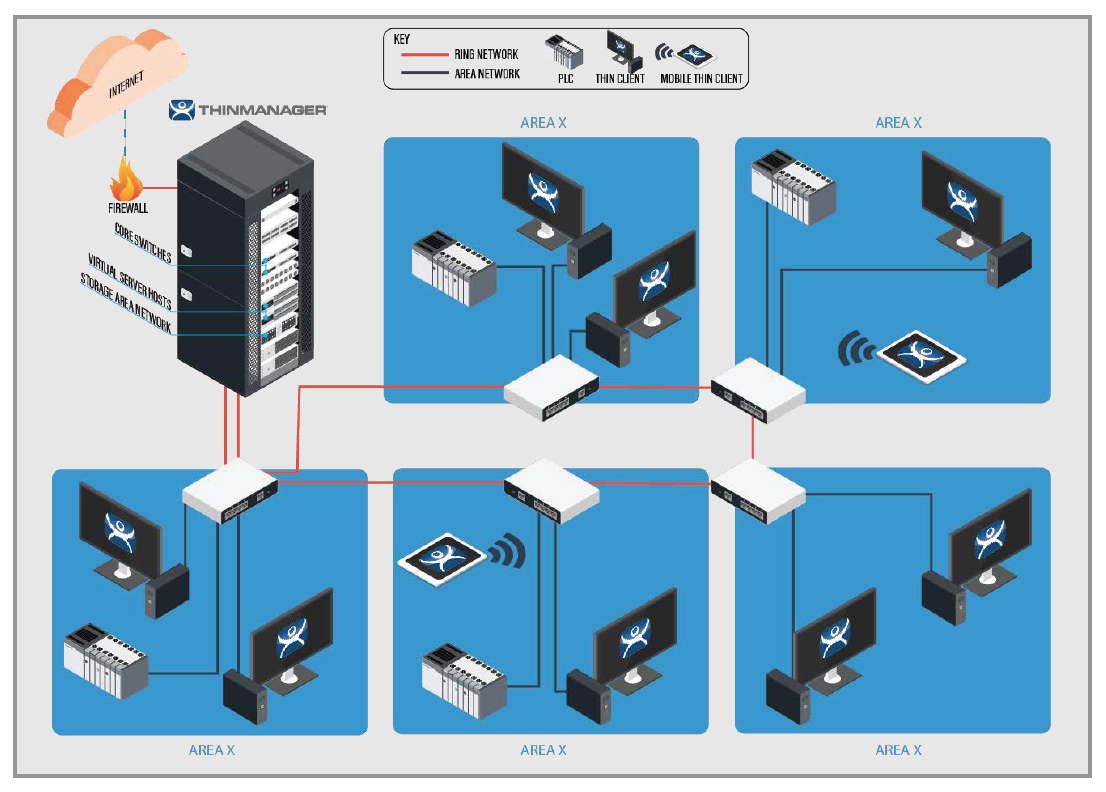

After their initial upgrade, the customer sat down with Robert to design an even more advanced system for a new facility with a network architecture based on their recent facility upgrade. Robert explained that they intended to push the envelope even further. “Because they are such a cutting edge company, they wanted to create something ultra modern that would still allow them flexibility because as they continue to patent new technologies there will be a need to continue to fine tune their process. They wanted a very clean Control Room with low power usage and heat output, as well as a desire to incorporate iPads instead of placing thin clients and additional network cables throughout the facility without sacrificing functionality of all the features ThinManager offers. Essentially, they designed this facility around ThinManager.”

Robert started by designing a facility wide intranet using WPA2 security on a segmented Layer 3 Wi-Fi network. By creating a separate VLAN and Subnet for the Wi-Fi and the control network and routing it to the ThinManager server, he ensured that if the network security was breached, the only thing that could be accessed would be ThinManager instead of the server controlling operations and data. Then to implement the ThinManager iTMC app, he hard coded the SSID for the Wi-Fi network directly into the iPad, which would render the Wi-Fi network invisible to any other device inside or outside the facility.

After completing the wireless architecture, Robert and the team from Third Evolution turned their attention to the Control Room. “We started with a basic ESX architecture using two VMware servers and one virtual server with Windows 2008R2 on each physical machine running redundant. Then we have five 55” screens. Three of them are on one Arista Box-240PC connected to one server using the ThinManager MultiMonitor feature, and the other two are connected to the backup ThinServer on a second Arista client,” Robert told us. “We designed it so that if any one piece of hardware failed, they wouldn’t lose their screens.”

After tying the network together, Robert began layering in ThinManager features to customize the facility operations and increase functionality. “We set up the Shadowing feature to make it easier to work remotely with the plant operators. We have ThinManager set up at the corporate office that we can access via VPN and use that to shadow them at the plant. If there is ever a problem, they can show us what they are doing, and we can provide accurate real time remote support. We also layered in ThinManager AppLink and IP Camera Support to deliver the integrated camera dashboard for advanced controls as well as for delivery of their Wonderware InTouch HMI.” By using AppLink he was able to set InTouch to deliver in full screen mode without having to configure each individual user with a separate batch file or security preferences.

The most impressive part of the Third Evolution architecture, however, was the integration of WinTMC and iTMC with the ThinManager installation at the facility and the corporate office. “Anyone with security clearance at their headquarters or one of their 150 satellite sites can monitor the plant processes without using hardcoded security credentials, resolution settings, or even an RDP connection. We just gave them an icon on their PCs and iPads, and they have full monitoring capability right at their fingertips. Even the President and Vice President of the company can use the app to connect via VPN and access the plant network from anywhere.”

After running for six months, Robert says the customer has not reported any problems with the system and that it is now part of the standard architecture for all of their facilities. “I think the ease of integration when deploying ThinManager is wonderful. Without the centralized management ThinManager delivers, we would have had to do a lot more work and had a system with less flexibility and security.”

We then asked him if he had any parting advice for other system integrators. “If you are going to use ThinManager, utilize it to its fullest. Don’t just use the bits and pieces you are comfortable with. It is simple to understand and deploy, and you won’t have to edit or restructure any of the software. We already have two more ThinManager deployments scheduled for this year, and we plan on introducing the end user to everything ThinManager has to offer.”

__________________________________________

To view our “Tips & Gems” video tutorials, visit our video links page here.

To review cost savings of using the ThinManager Platform, visit our ROI Calculator here.

To read about successful ThinManager Platform deployments, visit here.

To see when the next ThinManager 2-Day Training Session is being offered, visit here. [...]